Thermocoax offers various customised thermal solutions for a wide range of vacuum-related applications in numerous industrial settings.

Industries using vacuum processes need to be sure that suppliers’ products meet the highest standards of reliability and safety.

Thermocoax is a trusted name in the design and manufacture of a range of electrical thermal solutions that respond to clients’ needs in vacuum processes. Other applications include thermal chambers for R&D testing as well as sensors and transmission cables.

Custom Solutions for Vacuum Applications

Our customers include manufacturers of vacuum deposition machines, vacuum chambers and cryogenic facilities.

- Solar, semiconductor and industrial deposition

- Display and touch panel manufacturing

- Organic LED

- Analysis

- Cryogenics

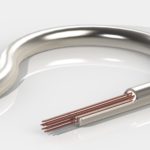

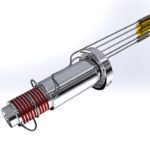

All our thermal solutions are equipped with mineral insulated cables: heaters, thermocouples, and signal transmission cables, manufactured in house.

Electrical Thermal Solutions

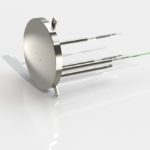

The engineering team at Thermocoax designs a whole range of thermal solutions suited to use in a vacuum. These include radiative heating plates, 2D and 3D shaped heating cables, ultra-high vacuum substrate heaters and rod heaters, and vaporisers.

All our thermal solutions are equipped with mineral insulated cable heaters and thermocouples, manufactured in house.

Tight Quality Control Procedures

To ensure that our products meet the highest standards, our manufacturing processes undergo tight internal controls in the area of quality and traceability.

- Full traceability of raw materials

- Subcontractor assessment

- Internal and external audits

- Regulatory compliance

Our vacuum-related range of solutions

For more information on our customised vacuum applications, please don’t hesitate to contact us.