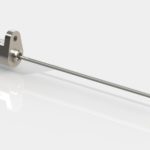

Thermocoax manufactures total thermal systems for temperature measurement with conductors, insulation and external sheaths combined in one cable.

Thermocoax manufactures a variety of temperature sensors for a wide range of manufacturing applications. Our sheathed thermocouples and heating cables are designed for extreme conditions, including vacuums. Customised solutions are available upon request.

We also provide solutions with resistance temperature detectors (RTDs) with high accuracy and repeatability.

Applications in Many Industrial Sectors including High Vacuum Environment

Thermocoax temperature sensors are designed to be deployed in all manner of industrial sectors, including metallurgy and glass, and a wide range of adverse conditions of temperature and pressure, etc.

The Cable Technology

The highly compact insulating power, the metallographic status of the conductors and the sheath, make the product highly flexible and enables temperature monitoring in locations that are difficult to access.

The mineral insulated cable technology offers high mechanical strength and protects the thermoelectric wires against oxidation, corrosion and chemical pollution.

Thermocoax thermal solutions are highly flexible and can be bent to a radius three times the outer diameter without damage.

Our sheathed thermocouples and heating cables can be easily mounted using various techniques, including adhesives, soldering, clamping, brazing, welding or sealing glands.

The sensor solutions come complete with temperature sensors and transmission cables.

Customisation and COFRAC Accreditation

Our R&D team has a wealth of experience in designing custom sensor solutions or complete thermal systems. All our products are equipped with our in-house manufactured MI cabling.

Thermocoax also has an in-house metrology department that specialises in the calibration of our thermocouple technology (accredited by COFRAC Calibration Section).

Temperature Sensors : Technical Data

- Fast response time = very short temperature variations

- Type J, K or N type, class 1

- Type S, R or B for high temperatures

- Easy shaping for integration

- No limits on length

- Range of diameters: 0.25 to 6 mm

For more detailed specifications and information about our temperature sensors, please do not hesitate to request a quote.