We offer electrical heaters and sensors for many industries whose applications can be very different, such as:

- Composite forming – Composite curing

- Plastics

- Thermoplastic welding

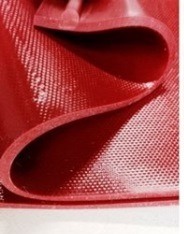

- Rubber vulcanisation

- High voltage (HV) cables and ultra-high voltage (UHV) cable manufacturing and maintenance

- Cement

- Powders

- Plexiglass

- Construction materials

- Cosmetics

We adapt and design custom electrical heaters and temperature sensors to meet the specific demands of each industry.

We adapt and design custom electrical heaters and temperature sensors to meet the specific demands of each industry.

- Silicon heating mats and mineral insulated cable heating plates for rubber vulcanisation systems

- Electrical heating plates for bulk solids

- Mineral insulated cable for heating moulds

- Heated hoses

- Infrared sources

- Custom thermal solutions integrating mineral insulated cable heaters and temperature sensors.